Se omisitsoeng ka kristale ea infrared bakeng sa R-PET Pelletizing/ Extrusion Line

Infrared Pre-Drying of PET Flakes: Ho eketsa Sephetho le ho Ntlafatsa Boleng ba PET Extruders

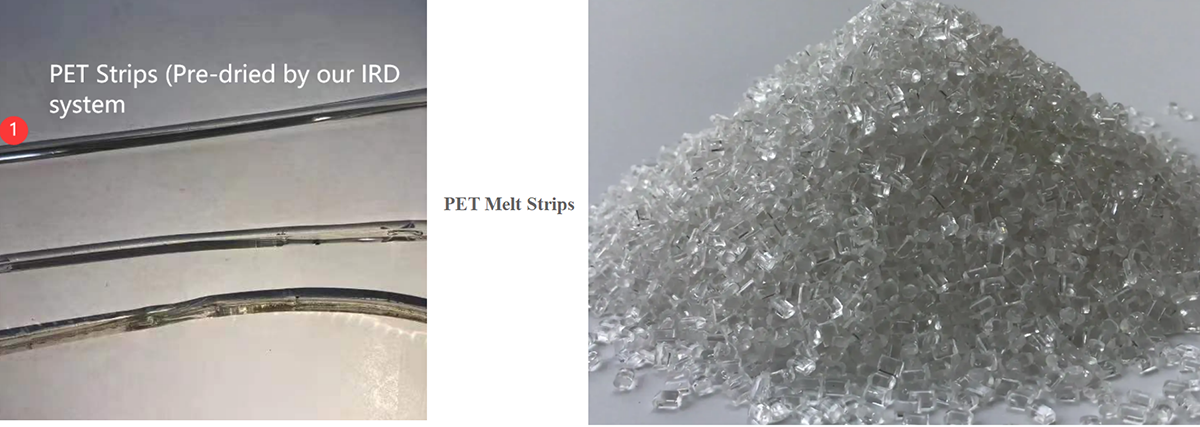

>> Ho lokisa li-flakes ho extruder ho fokotsa IV ka lebaka la hydrolysis i boteng ba metsi,ke ka lebaka leo ho omisa pele ho boemo ba ho omisa ka mokhoa o ts'oanang le IRD System ea rona ho ka fokotsang phokotso ena. Ho phaella moo, resin ha e mosehla hobane nako ea ho omisa e fokotsehile (Nako ea ho omisa e hloka feela 15-20mins, mongobo oa ho qetela o ka ba joalo≤ 50ppm, tšebeliso ea matla e ka tlase ho 80W/KG/H), 'me ho kuta ka har'a extruder ho boetse ho fokotsehile hobane thepa e chesitsoeng pele e kena ka har'a extruder ka mocheso o sa khaotseng "

>> Mohato oa pele, PET regrind e khabisitsoe ebe e omisoa ka har'a IRD ka nako ea metsotso e ka bang 15. Ts'ebetso ena ea crystallization le ho omisa e finyelloa ka mokhoa o tobileng oa ho futhumatsa mocheso o sebelisang mahlaseli a Infrared, ho finyella mocheso oa thepa oa 170˚C. Ho fapana le mekhoa e liehang ea moea o chesang, ho kenya letsoho ka potlako le ka ho toba ho etsa hore ho be le egalisation e phethahetseng ea litekanyetso tse feto-fetohang tsa mongobo o kenang ka ho sa feleng - mokhoa oa ho laola mahlaseli a IR o lumella ho arabela maemo a fetohileng a ts'ebetso ka metsotsoana. Ka tsela ena, boleng bo pakeng tsa 5,000 le 8,000 ppm bo fokotsoa ka homogeneously ka hare ho IRD ho isa boemong ba mongobo o ka bang 30-50ppm.

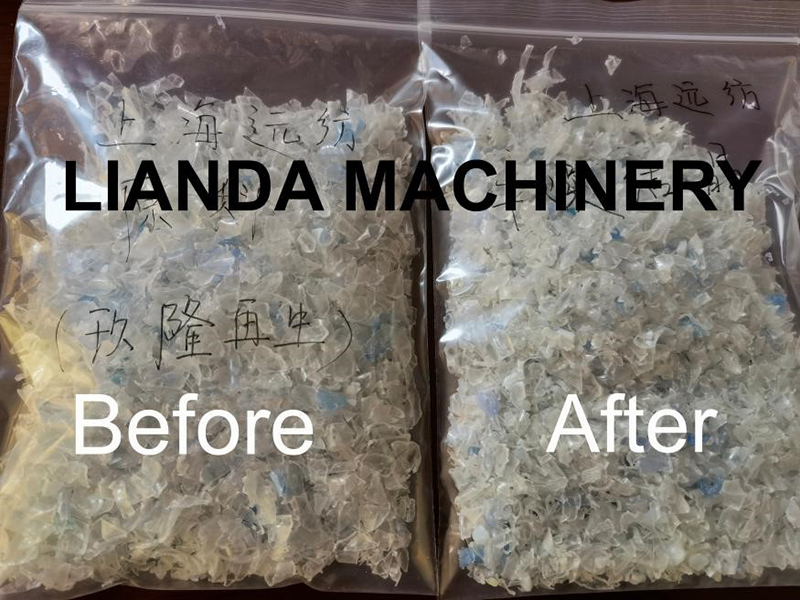

>>E le phello ea bobeli ea ts'ebetso ea crystallization ho IRD, bongata ba thepa ea fatše boa eketseha,haholo-holo ka li-flakes tse boima bo bobebe haholo. Phello ena ea bobeli e khahla haholo khahlano le bokamorao ba hore tšekamelo ea ho sheba libotlolo tse nang le mabota a masesaane e thibela lisebelisoa tsa ho sebelisoa hape ho fihlela boima ba boholo ba > 0.3 kg/dm³. Keketseho ea bongata ba bongata ka 10 ho isa ho 20% e ka finyelloa ho IRD, e bonahalang e se letho qalong, empa e ntlafatsa ts'ebetso ea phepelo sebakeng sa extruder haholo - ha lebelo la extruder le ntse le sa fetohe, ho na le ntlafatso e kholo. ho tlatsa tshebetso holim'a screw.

Nako ea poso: Apr-07-2023