PET Bottle Flake Granulation Line

PET Bottle Recycling Pelletizer PET Granulation Machine Process flow

Tlhaloso ea Setsebi

|

Lebitso la Mochini |

PET Single Screw Extrusion pelletizing Line |

|

Lisebelisoa tse so ntlafatsoe |

rPET Flakes |

|

Sehlahisoa sa ho qetela |

rPET Pellets |

|

Likarolo tsa Line ea Tlhahiso | Sistimi ea ho omisa kristale ea infrared: Vacuum feeder/ Se omisa kristale ya infrared/ Sehlahisoa sa vacuum

Mohala o le mong oa Screw Extrusion granulating: Mochini o le mong oa screw main extruder/Hydraulic Double Pistons screen changer/Hlooho e shoang/Sekotlolo sa metsi a hlatsuoang/Flushing pellitizer/Mochini o ntšang metsi o otlolohileng/Mochini o sisinyehang oa sieve/ Polokelo

|

|

Screw diameter |

90mm-150mm |

|

L/D |

1:24/1:30 |

|

Sebaka sa tlhahiso |

150-1000KG/H |

|

Screw material |

38CrMoAlA ka kalafo ea Nitrding |

|

Mofuta oa Pelletizing |

Ho hlatsuoa ha metsi le pelletizing |

|

Ho fetola skrine |

Hydraulic Double Pistons Screen Changer |

Lintlha tsa Mochini

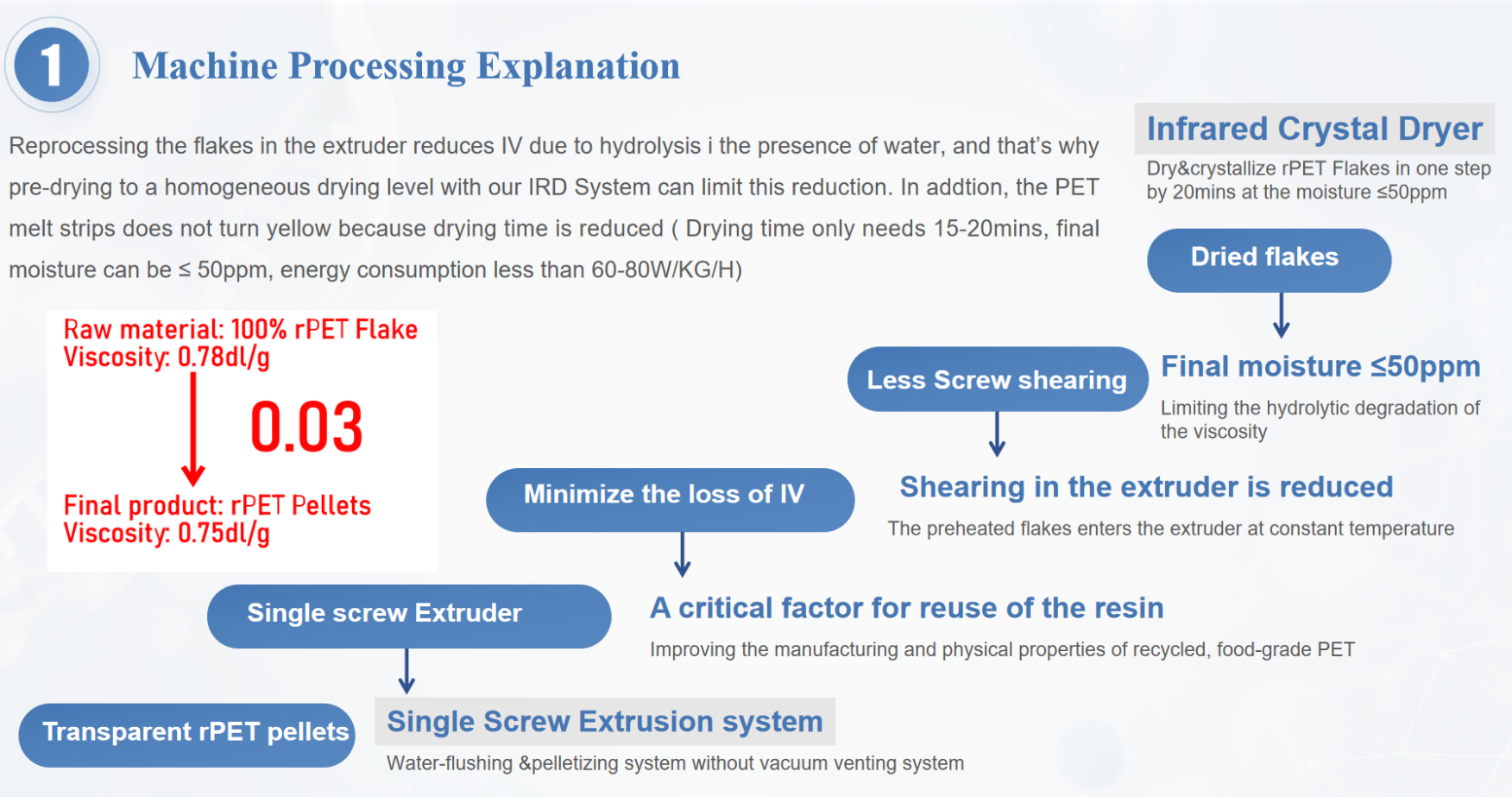

Infrared Crystal Dryer (LIANDA PATENT DESIGN)

①Ho ntlafatsa thepa le thepa ea 'mele ea PET e sebelisoang hape, ea boemo ba lijo ka theknoloji e tsamaisoang ke leqhubu la infrared e na le karolo ea bohlokoa eo e lokelang ho e bapala thepa ea intrinsic viscosity (IV)

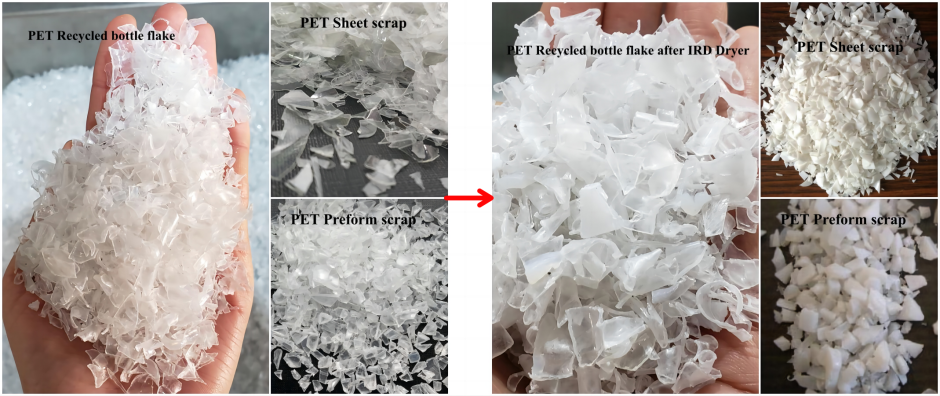

②Pre-crystallization le ho omisoa ha li-flakes pele ho extrusion ho thusa ho fokotsa tahlehelo ea IV ho tsoa ho PET, ntlha ea bohlokoa bakeng sa ho sebelisoa hape ha resin.

③Ho lokisa li-flakes ka har'a extruder ho fokotsa IV ka lebaka la hydrolysis boteng ba metsi, ke ka lebaka leo ho omisa pele ho boemo ba ho omisa ka mokhoa o ts'oanang le IRD System ho ka fokotsa phokotso ena.

Ho phaella moo, lihlopha tsa PET tse qhibilihisang ha li fetohe mosehla hobane nako ea ho omisa e fokotsehile ( Nako ea ho omisa e hloka feela 15-20mins, mongobo oa ho qetela o ka ba ≤ 30ppm, tšebeliso ea matla e ka tlase ho 60-80W / KG / H)

④ Ho kuta ka har'a extruder ho boetse ho fokotsehile hobane thepa e futhumetseng e kena ka har'a extruder ka mocheso o sa khaotseng "

⑤Ho ntlafatsa tlhahiso ea PET Extruder

Keketseho ea bongata ba bongata ka 10 ho isa ho 20 % e ka finyelloa ho IRD, ea ntlafatsa ts'ebetso ea phepelo sebakeng sa extruder haholo - ha lebelo la extruder le ntse le sa fetohe, ho na le ts'ebetso e ntlafalitsoeng haholo ea ho tlatsa sekoti.

Mohala o le Mong oa Screw Extrusion Pelletizing Line (ntle le Vacuum Venting)

Ka ho sebelisa matla a Single screw extruder le ho e penta ka LIANDA e entsoeng ka mokhoa o ikhethileng bakeng sa rPET Bottle flakes, re khonne ho eketsa bokhoni ka 20% ka matla a fokolang a sebelisoang ha a bapisoa le Parallel double screw extruder.

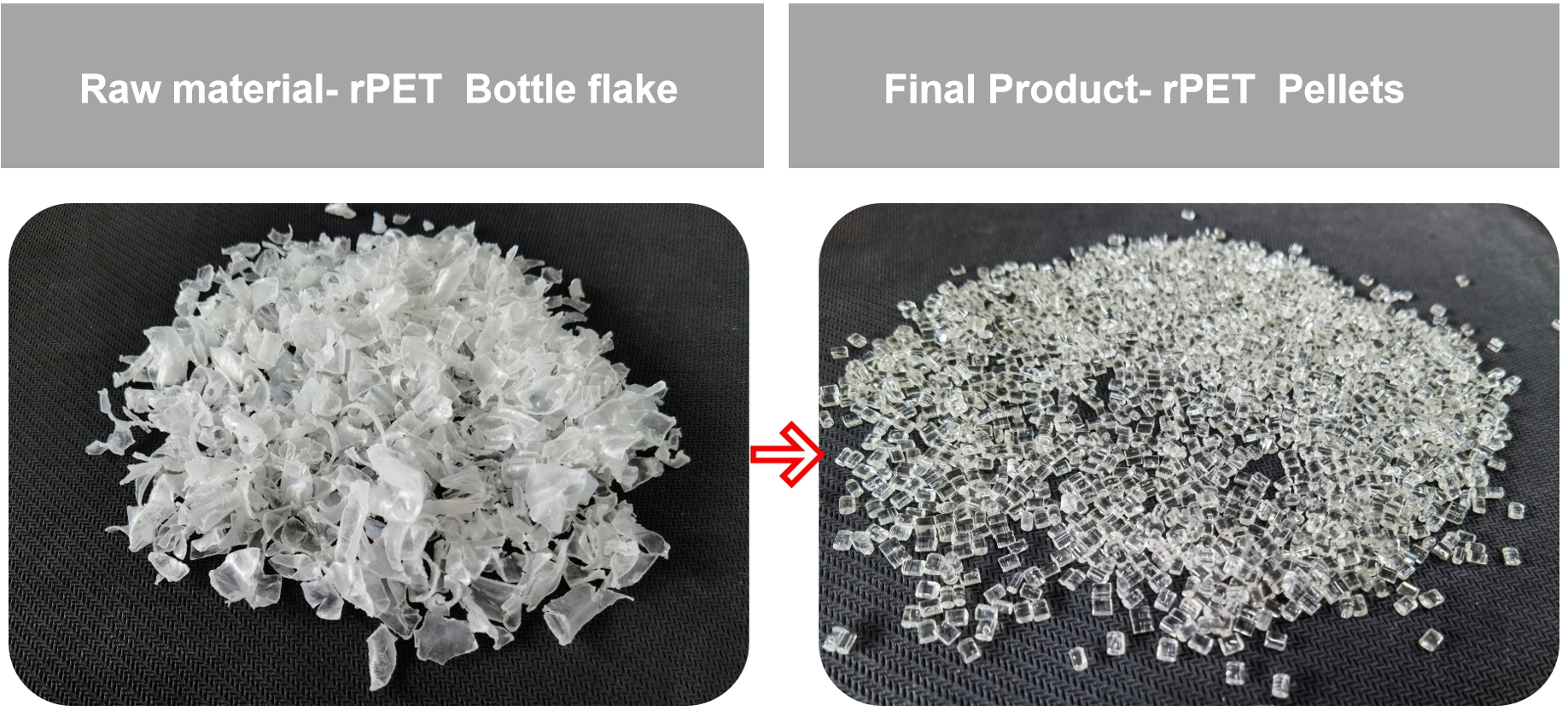

Viscosity ea li-pellets tsa rPET tse hlahisoang ke tsamaiso ea rona: ho na le ≤0.02-0.03dl/g viscosity drop feela ---ntle le ho eketsa leha e le efe ea viscosity enhancer. ( Ho latela tlhahlobo ea rona ea ka tlung)

rPET pellets Colour: transparent --- ntle le ho eketsa pepeneneng efe kapa efe

Ntle le sistimi ea Vacuum venting --- Ho boloka litšenyehelo tsa matla, ho se na mathata le ho sebetsa ka mokhoa o tsitsitseng

Linepe tsa mochini