PET Flake / scrap dehumidifier crystallizer

Mohlala oa Kopo

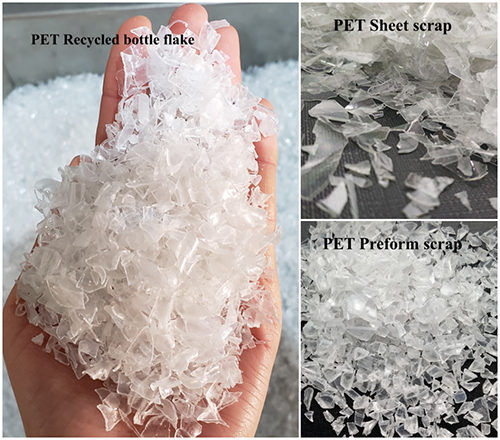

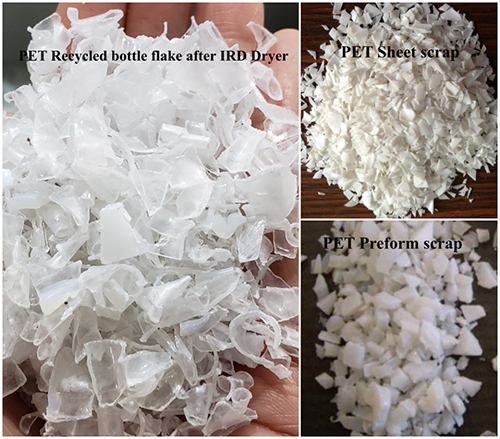

| Lisebelisoa tse so ntlafatsoe | PET Recycled flake/ PET sheet scrap/PET Preform scrap |

|

| Ho sebelisa Mochini | LDHW-600 * 1000 |  |

| Ho omisa & Crystallized Mocheso sete | 180-200 ℃E ka feto-fetoha ka thepa ea lihlahisoa tse tala | |

| Crystallized nako e behiloeng | 20metsotso | |

| Boitsebiso ba ho qetela | Likhechana tsa PET tse khabisitsoeng le tse omisitsoeng lemongobo oa ho qetela o ka ba 30ppm |  |

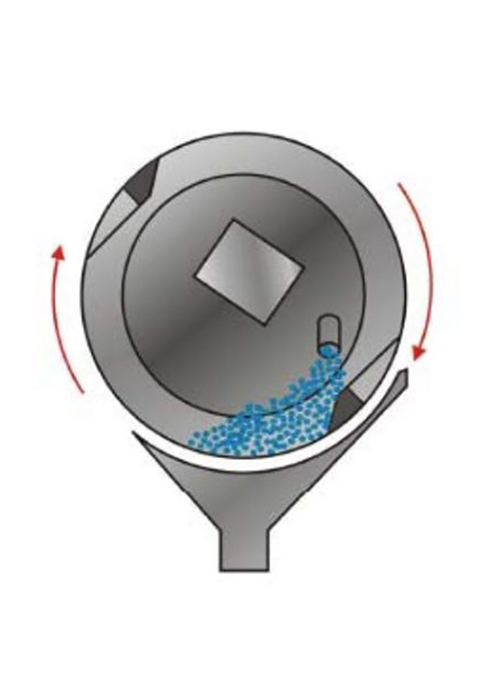

Mokhoa oa ho Sebetsa

Ho fepa/Loading

Ts'ebetso e omileng le ea Crystallization

Ho qhala

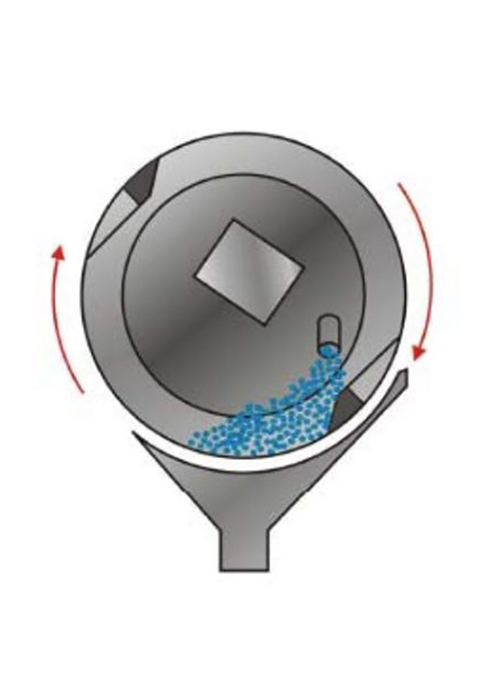

>> Mohato oa pele, sepheo se le seng feela ke ho futhumatsa thepa ho fihlela mocheso o seng o setiloe.

Amohela lebelo le batlang le lieha la ho potoloha ha moropa, matla a mabone a Infrared a omisitsoeng a tla ba boemong bo holimo, ebe li-pellets tsa PET li tla futhumala ka potlako ho fihlela mocheso o nyolohela mochesong o behiloeng esale pele.

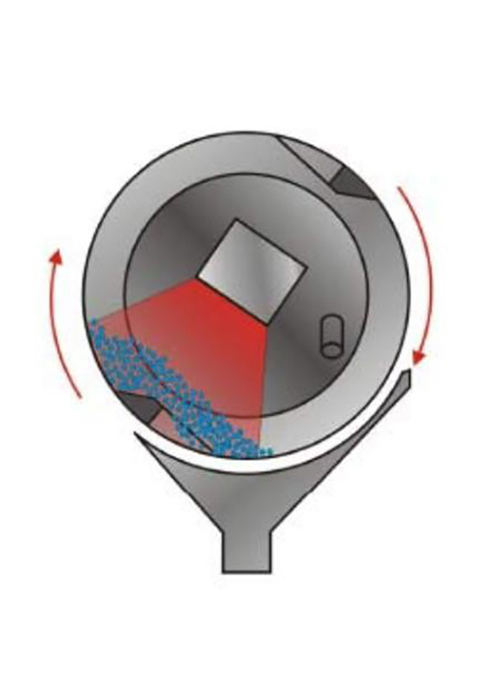

>> Ho omisa & Crystallizing mohato

Hang ha thepa e fihla mochesong, lebelo la moropa le tla eketsoa ho lebelo le phahameng haholo la ho potoloha ho qoba ho bokellana ha thepa. Ka nako e ts'oanang, matla a mabone a infrared a tla eketsoa hape ho qeta ho omisa. Joale lebelo la ho potoloha ha moropa le tla fokotsoa hape. Ka tloaelo mokhoa oa ho omisa o tla phethoa ka mor'a 15-20mins. (Nako e nepahetseng e itšetlehile ka thepa ea thepa)

>> Kamora ho qeta ts'ebetso ea ho omisa, Drum ea IR e tla ntša thepa ka bo eona ebe e tlatsa moqomo hape bakeng sa potoloho e latelang.

Ho tlatsa hape ka othomathiki hammoho le liparamente tsohle tse amehang bakeng sa litselana tse fapaneng tsa mocheso li kenyelelitsoe ka botlalo taolong ea boemo ba morao-rao ea Touch Screen. Hang ha li-parameter le li-profiles tsa mocheso li fumanoa bakeng sa thepa e itseng, litlhophiso tsa thesis li ka bolokoa e le diresepe tsamaisong ea taolo.

Molemo oa Rōna

Ka tloaelo PET Bottle flakes kapa sheet scrap le boemo ba pele ba mongobo ho fihla ho 10000-13000ppm. PET Bottle flakes kapa sheet scrap (Moroetsana kapa e tsoakiloeng) e tla nchafatsoa ka infrared crystal dryer ka 20mins, mocheso o omisang o tla ba 150-180 ℃ ebe o omisoa ho 50-70ppm, ebe o fepeloa ho Single screw extruding system bakeng sa ts'ebetso e tsoelang pele.

● Ho fokotsa ho senyeha ha hydrolytic ea viscosity.

● Thibela ho eketseha ha maemo a AA bakeng sa lisebelisoa tse amanang le lijo

● Ho eketsa bokhoni ba mohala oa tlhahiso ho fihlela ho 50%

● Ntlafatsa le ho etsa hore boleng ba sehlahisoa bo tsitse-- Mongobo o lekanang le o phetoang oa thepa

● Ho fihla ho 60% ho fokotseha ha tšebeliso ea matla ho feta mokhoa o tloaelehileng oa ho omisa

● Ha ho na karohano ea lihlahisoa tse nang le mefuta e fapaneng ea bongata

● Mocheso o ikemetseng le nako ea ho omisa e behiloeng

● Ho hloekisa habonolo le ho fetola thepa

● Ho qala hang-hang le ho koala kapele

● Ho khabisa ka mokhoa o tšoanang

● Ha ho li-pellets tse khomarelang le ho khomarela

● Ho tšoara lintho ka hloko

Lethathamo la Papiso

| Ntho | IRD Dryer | Se omisitsoeng se Tloaelehileng |

| Mokhoa oa ho fetisa | Ha ho letho | Moea o chesang |

| Phetiso ea mocheso | Ka bobeli ka hare le ka ntle likaroloana hammoho. | Ho tloha ka ntle ho ea ka hare ho karoloana butle-butle. |

| Matla | Boloka bonyane matla a 20 ~ 50% ha a bapisoa le se omisang se tloaelehileng. | Sebelisa matla a mangata. |

| Nako ea ts'ebetso | 1. Crystallization & drying: Li sebetsoa ka nako e le 'ngoe nakong ea metsotso e ka bang 8 ~ 15. 2. Ho omisa le crystallization ka nako | 1. Crystallization: Hoo e ka bang metsotso e 30 ~ 60. 2. Ho omisa: Hoo e ka bang lihora tse 4 ~ 6. |

| Mongobo | 1. Tlas'a 50-70 PPM ka mor'a hore IRD e sebetsoe. | 1. Sebelisa metsotso e 30 ~ 60 ho fetola PET ea amorphous ho PET e khanyang pele. 2. Tlas'a 200PPM ka mor'a lihora tse ka bang 4 dehumidifier e sebetsoa. 3. Tlas'a 50 PPM ka mor'a lihora tse ka bang 6 hore dehumidifier e sebetsoe. |

| Lead time | 20metsotso | Ho feta lihora tse 6. |

| Phetoho ea lintho tse bonahalang | 1. Ho bonolo le kapele. 2. Ho na le makhetlo a 1 ~ 1.5 feela a tšebeliso ea thepa ka hora ka har'a buffer hopper. | 1. Ho thata & butle. 2. Ho na le makhetlo a 5 ~ 7 bokhoni ba tšebeliso ea thepa ka hora ho crystallizer & hopper. |

| Tshebetso | E bonolo--- Ka taolo ea Siemens PLC

| Ho thata joalo ka ha e tlameha ho kenya PET e nyane ka har'a kristale ha e qala ts'ebetso. |

| Tlhokomelo | 1. E bonolo. 2. Litšenyehelo tse tlase tsa tlhokomelo. | 1. Thata. 2. Litšenyehelo tse phahameng tsa tlhokomelo. |

Linepe tsa mochini

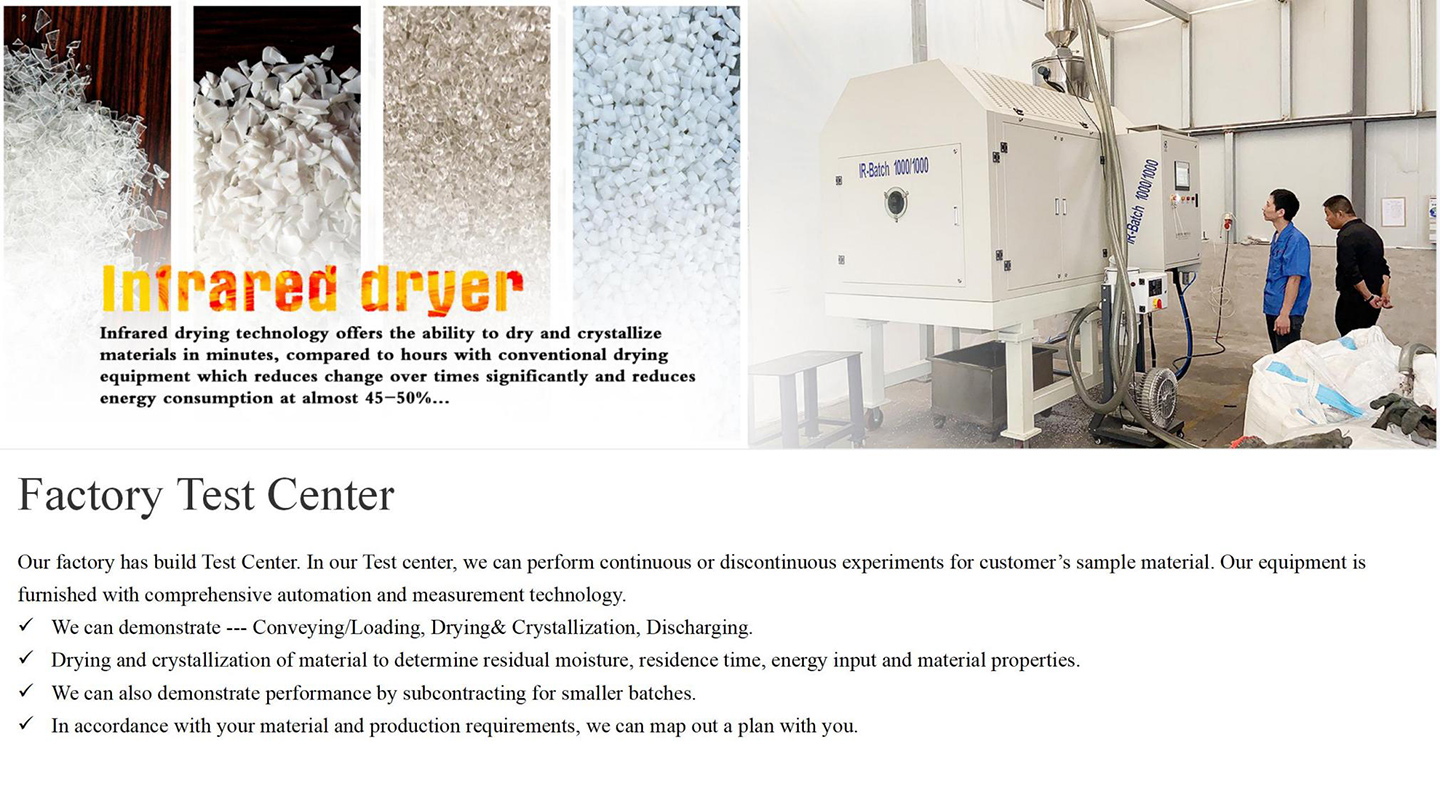

Tlhahlobo ea mahala ea lintho tse bonahalang

Moenjiniere ea nang le boiphihlelo o tla etsa tlhahlobo. Basebetsi ba hau ba memeloa ka mofuthu ho nka karolo litseleng tsa rona tse kopaneng. Kahoo u na le monyetla oa ho kenya letsoho ka mafolofolo le monyetla oa ho bona lihlahisoa tsa rona li sebetsa.

Kemiso ea Mochini

>> Fana ka moenjiniere ea nang le boiphihlelo fekthering ea hau ho thusa ho kenya le ho etsa liteko tsa thepa

>> Adopt aviation plug, ha ho hlokahale ho hokela terata ea motlakase ha moreki a fumana mochini fekthering ea hae. Ho nolofatsa mohato oa ho instola

>> Fana ka video ea ts'ebetso bakeng sa ho kenya le ho tsamaisa tataiso

>> Ts'ehetso ea litšebeletso tsa marang-rang