Sekhahla sa shaft habeli

Sekhahla sa shaft habeli

Double shaft shredder ke mochini o feto-fetohang haholo.Moqapi oa theknoloji ea ho kuta ka torque e phahameng o ka finyella litlhoko tsa ho tsosolosa litšila 'me o loketse ho senya lisebelisoa tse kholo tsa molumo, tse kang likhetla tsa koloi, lithaere, libarele tsa tšepe, aluminium e lahliloeng, tšepe e senyehileng, litšila tsa ntlo, litšila tse kotsi, litšila tsa indasteri, joalo-joalo. e ka etsoa ho latela litlhoko tsa bareki le lisebelisoa tse sebetsitsoeng ho eketsa melemo ea basebelisi.

>> Mochine o na le litšobotsi tsa torque e kholo ea phetisetso, khokahano e tšepahalang, lebelo le tlase, lerata le tlase, le litšenyehelo tse tlase tsa tlhokomelo.Karolo ea motlakase e laoloa ke lenaneo la Siemens PLC, ka ho lemoha ka mokhoa o itekanetseng oa tšireletso e feteletseng.Motlakase oa mantlha Likarolo li nka mefuta e tsebahalang joalo ka Schneider, Siemens, ABB, joalo-joalo.

Lintlha tsa Mochini li bontšitsoe

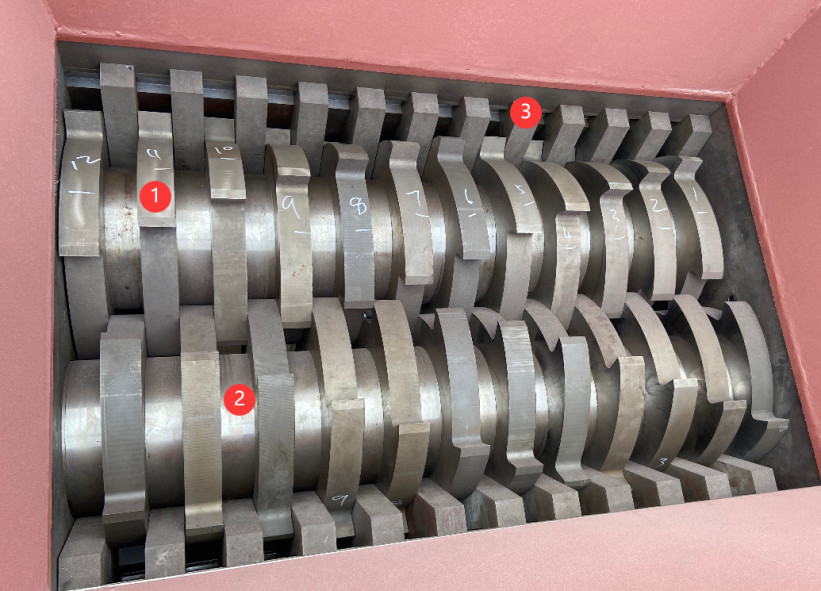

>> Karolo ea blade shaft

① Li-blades tsa Rotary: lisebelisoa tsa ho seha

②Spacer: Laola lekhalo la mahare a rotary

③ Li-blade tse tsitsitseng: thibela lisebelisoa hore li se ke tsa phuthela ka har'a shaft ea lehare

>> Lisebelisoa tse fapaneng li amohela mofuta o fapaneng oa blade rotor

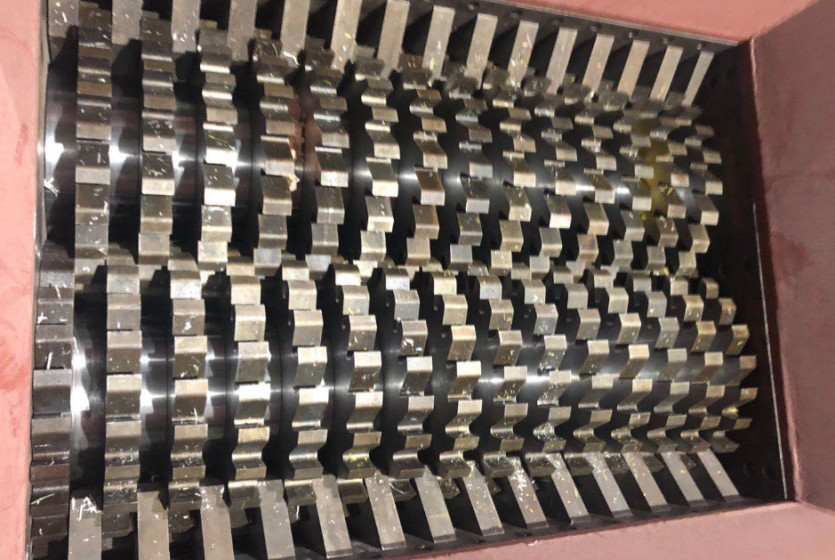

>> Li-blades li hlophisitsoe ka mohala oa spiral ho lemoha ho itšeha hantle

>> Lisebelisoa tse fapaneng li amohela mofuta o fapaneng oa blade rotor

>> Ka bobeli lesoba le ka hare la sesebelisoa le bokaholimo ba ho ohla li nka moralo oa hexagonal ho hlokomela ho tšoana ha matla a lehare.

>> Arohane moralo oa setulo ho thusa ho boloka le ho lokisa lirota

>> Bearing e tiisitsoe, ha e kenelle metsi ebile e thibela lerole.

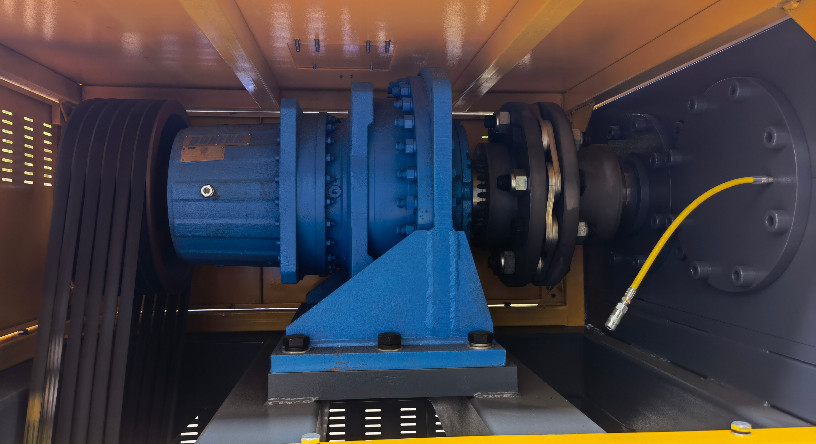

>> Amohela se fokotsang lisebelisoa tsa polanete, ho matha hamonate le ho hana ho thothomela

>>Siemens PLC e beha leihlo lebelo la motlakase ka nako ea nnete, 'me axis ea thipa e fetoha ka bo eona ha mojaro o tletse ho sireletsa koloi;

Mochine oa Tekheniki Parameter

| Mohlala

| LDSZ-600 | LDSZ-800 | LDSZ-1000 | LDSZ-1200 | LDSZ-1600 |

| Matla a motlakase a ka sehloohong KW | 18.5*2 | 22*2 | 45*2 | 55*2 | 75*2 |

| Bokhoni KG/H | 800 | 1000 | 2000 | 3000 | 5000 |

| Boemo mm | 2960*880*2300 | 3160*900*2400 | 3360*980*2500

| 3760*1000*2550 | 4160*1080*2600 |

| Boima ba 'mele KG | 3800 | 4800 | 7000 | 1600 | 12000 |

Mehlala ea Kopo

Sebaka sa koloi

Mohala oa Motlakase

Senya thaere

Moropa oa tšepe

LIHLOOHO TSA MOSEBETSI>>

>> Moralo o kopaneng oa lebokose la thipa, o tsitsitse ebile o ka tšeptjoa

Integral thipa lebokose, annealing kalafo ka mor'a hore tjheseletsa, ho etsa bonnete ba molemo mochine matla;Ka nako e ts'oanang, tšebeliso ea mechine ea ho laola NUMERICAL, ho etsa bonnete ba ho nepahala ho phahameng ho sebetsa, ho lelefatsa bophelo ba tšebeletso ea lisebelisoa, ho boloka litšenyehelo tsa tlhokomelo.

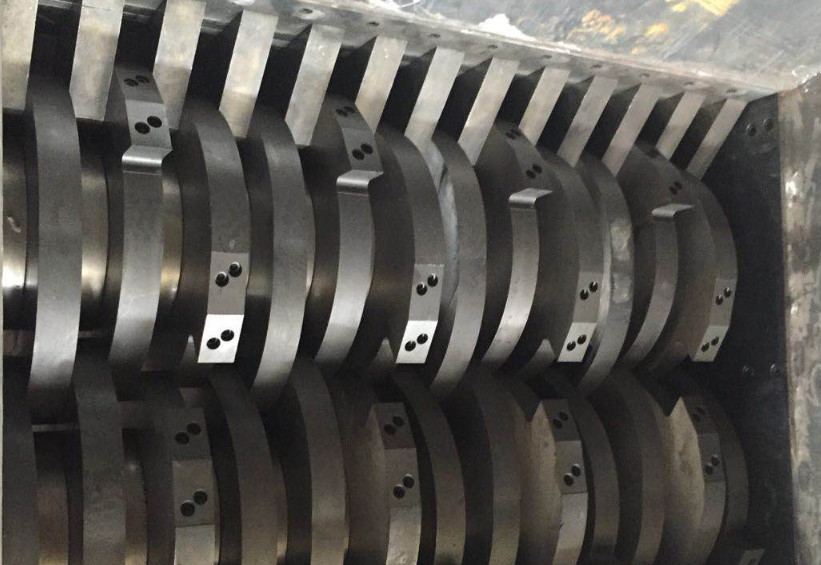

>> Thipa e tsitsitseng e ikemetse ebile e ka tlosoa, e na le khanyetso e matla ea ho apara

Thipa e 'ngoe le e' ngoe e tsitsitseng e ka aroloa ka boithaopo le ho kenngoa, e ka qhaqhoang ka nako e khutšoanyane, e fokotsa haholo mosebetsi oa basebetsi le ho ntlafatsa tsoelo-pele ea tlhahiso.

>> Moralo o ikhethileng oa li-blade, ho bonolo ho o hlokomela le ho o nkela sebaka

Li-blades tsa ho itšeha li entsoe ka tšepe ea alloy e tsoang linaheng tse ling e nang le nako e telele ea tšebeletso le ho fapanyetsana ho hotle, ho leng bonolo ho boloka le ho nkela sesebelisoa sa ho itšeha sebakeng sa morao-rao.

>> Matla a spindle, ho hanyetsa mokhathala le ho hanyetsa tšusumetso

The spindle e entsoe ka tšepe ea alloy e matla haholo, e 'nileng ea phekoloa ka mocheso ka makhetlo a mangata' me ea sebetsoa ka mokhoa o nepahetseng haholo.E na le matla a matle a mochine, ho hanyetsa ka matla ho mokhathala le tšusumetso le bophelo bo bolelele ba tšebeletso.

>> Li-bearings tse tsoang linaheng tse ling, litiiso tse ngata tse kopantsoeng

Li-bearings tse tsoang linaheng tse ling le litiiso tse ngata tse kopantsoeng, ho hanyetsa mojaro o phahameng, bophelo bo bolelele ba tšebeletso, ho thibela lerōle, ho thibela metsi le ho thibela metsi, ho netefatsa ts'ebetso e tsitsitseng le e tsitsitseng ea mochine.

Linepe tsa mochini